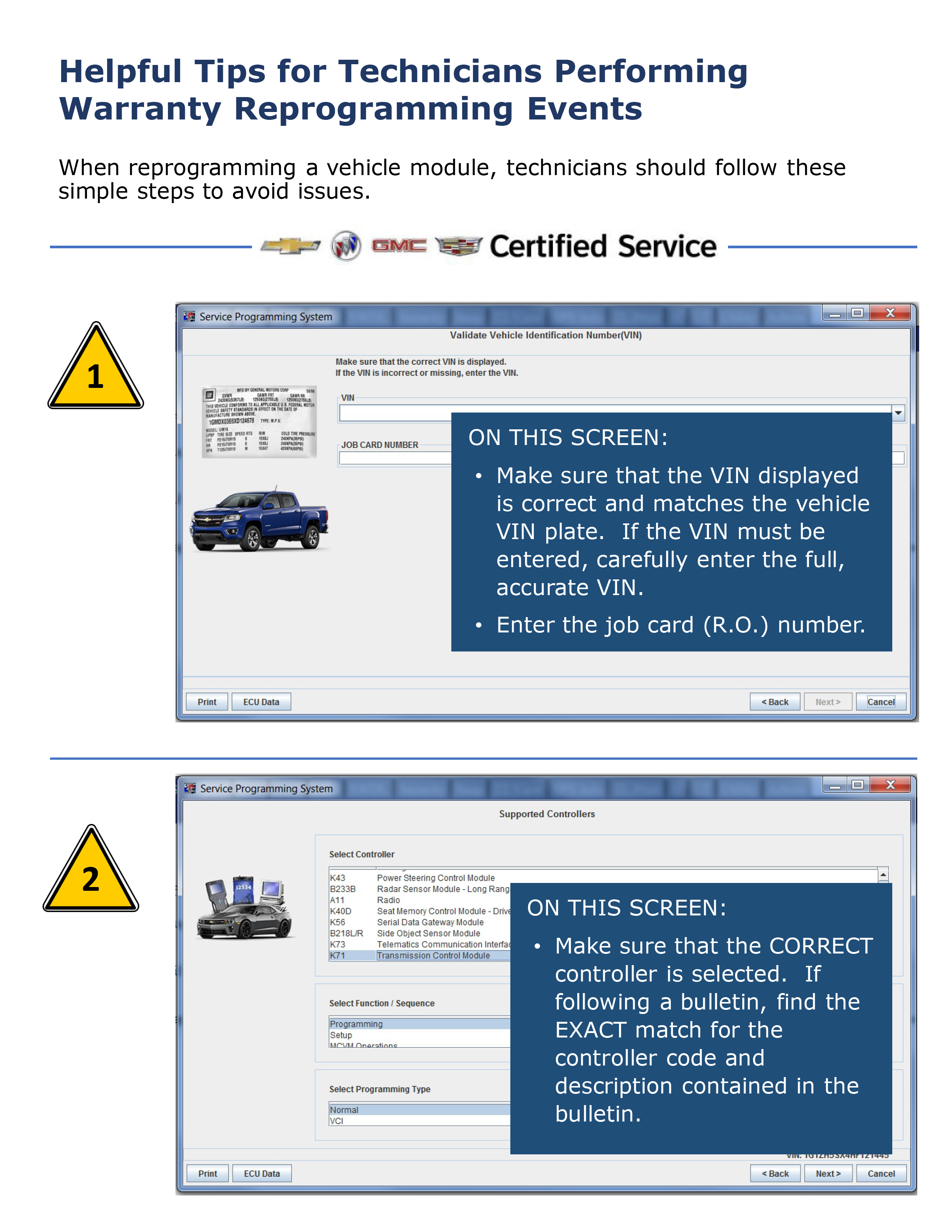

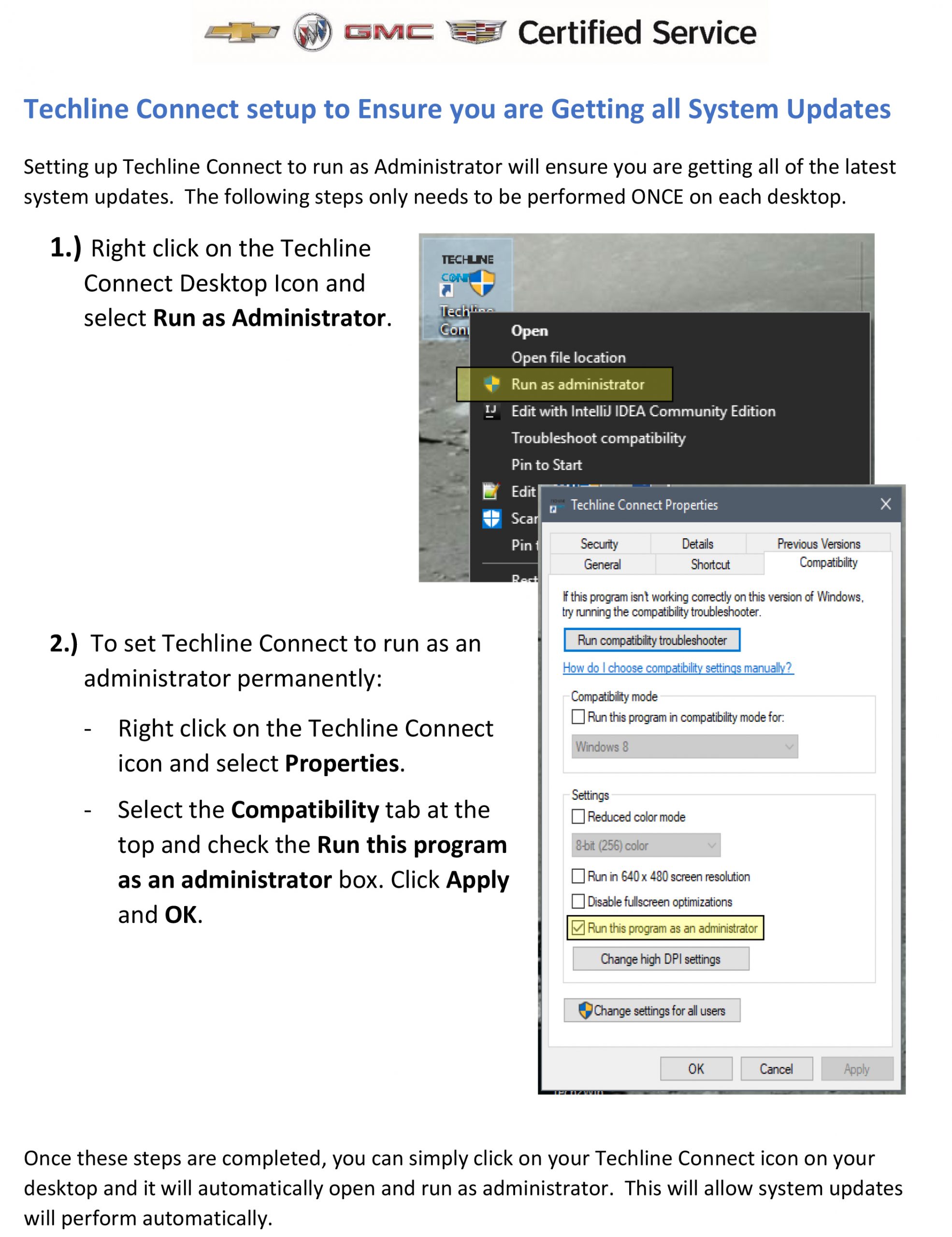

When performing internal transmission repairs on GM transmissions (Fig. 1) under warranty, current labor times focus on replacing the damaged part(s), with Other Labor Hours (OLH) as the only option for diagnosis or inspection and cleaning procedures for re-using components that are part of the overall transmission repair. The focus on part replacement can lead some technicians to be hesitant to spend too much time on the diagnostic and cleaning procedures necessary to identify and perform all aspects of a transmission repair. This labor time policy of using OLH for work beyond the base repair also can act as a disincentive for some technicians to invest in the training needed to become a specialized transmission technician. GM is out to change that.

Fig. 1

By listening to many dealership technicians about their concerns with transmission labor times and related transmission repair procedures, GM is updating the Labor Time Guide with new Add Times for transmission diagnosis, cleaning and inspections. The goal is to assure technicians that the labor time for a complete transmission repair will cover all of the actual time spent on the repair.

The updated Add Times allowances will still require technician comments and punch times to support the extra time spent on repairs, but Service Management approval is not required as long as the time claimed is within the variable published allowance. And for difficult repairs that exceed the Add Time allowance, OLH is still available to cover the extra time needed with Service Management authorization.

The new Add Times will bring transmission repairs more in line with the allowances for transmission replacements, where technicians are allowed Add Time for diagnosis as well as add time for disassembly and assembly.

Updated Add Times

Add Times will be released for select internal repairs on all GM automatic transmissions over several months, beginning with 6-speed transmissions in the May Labor Time Guide. Published allowances (Fig. 2) will be:

Diagnosis Time – 0.0-1.0 hr.

- You may claim up to the allowable labor hours depending on actual time to perform diagnosis, i.e., test drive, pressure tests, GDS2 diagnostics, etc.

Cleaning and Inspection – 0.0-2.0 hr.

- You may claim up to the allowable labor hours depending on actual time to clean debris and inspect components for reuse. For example, when a component failure has introduced metal throughout the transmission, requiring further teardown, cleaning, and inspection of parts to determine if they can be reused.

Fig. 2

在劳动时指南中释放新增时间的推出是:

May 1, 2021 –6速自动变速箱

June 1, 2021 –8-speed and 9-speed automatic transmissions

July 1, 2021 –10-speed automatic transmissions, Allison transmissions, electric powertrains

With the new Add Times, technicians can be sure that their time spent on the necessary procedures – including diagnosis, inspections and cleaning – will be covered to make a proper transmission repair without OLH.

– Thanks to Steve Bruder and Mark Kevnick

Updated April 30, 2021

Being a Certified Master Technician for GM dealerships ,specializing in transmissions with over 45 years experience , I have watched transmission times be cut to literally near nothing as compared to back in the day. I have watched and been a part of GM’s technology taking us from simplistic models to some of the most advanced units in the world. Clearly with this change in the labor times manual, GM is finally figuring out that the labor times have diminished to the point that GM has lost most of their ability to hire and maintain Transmission Technicians that have the ability to properly diagnosis and repair transmissions and drive lines. I have not seen the updated labor time guide yet but I hope that it finally compensates trans techs for their time. Thank you

需要ab OLH仍可用于维修ove the 1.0 diagnosis and 2.0 clean and inspect add times. Using your example for multiple failures, the torque convertor should be used as the causal part for the type of failure described. For any subsequent failures, such as the clutch or pumps, use OLH to repair those items.

I am a Transmission Specialist at a very busy dealership. Because there are limited Technicians that do Transmission repairs, we get a lot of business from surrounding dealers. I average 6-8 transmissions a week, a majority of them being the 6Ls. Many of these units that I tear apart as a result of torque converter failure have other distressed components that need reconditioned, such as clutch components, fluid pumps and housings. I am very familiar with the 6Ls, but even so 2 hours just isn’t enough time to properly and thoroughly clean all the internals. Maybe in a very minor case, but 90% if not more of the 6Ls I see have extensive metal contamination and require full on overhauls. Meaning clutch housings disassembled, pistons removed, valve bodies separated, and pump disassembled. I spend minimum of 4 hours inside a unit reconditioning it, due to the severe amount of metal debris contamination incurred from the torque converter failures. I also don’t ever have comebacks, which I attribute to the ability to be able to spend the necessary time to perform a proper repair. If the goal is to ensure that us Technicians get compensated for our time, then there cannot be such a low amount of time allotted for such an intricate and complex repair. I have concerns about how this will effect my ability to do a thorough repair.

1. When a unit has severe failure and metal contamination which would require more than 2 hours of cleaning time spent to properly ensure all metal contaminates are out of the unit, is OLH still available or do we just utilize the time spent best as possible?

2. When there is multiple failures, how do we get compensated for the extra amount of time spent repairing/reconditioning those other components? Example: Most common failure on a 6L is a torque converter, but often times takes out the 4-5-6 clutches and the pump as a result of the failure. Using the converter as the causal part, how do we get the added time spent addressing these other subsequent failures/damage?