腐蚀或剥离的电接地连接可能导致模块通信和其他电气系统发生故障,导致不必要的维修和零件更换。电气系统依赖于固定的无腐蚀接地连接,以便正常工作,因此必须修复任何损坏的接地连接,以提供具有低电阻接地路径的良好安装点,以及防止未来腐蚀。

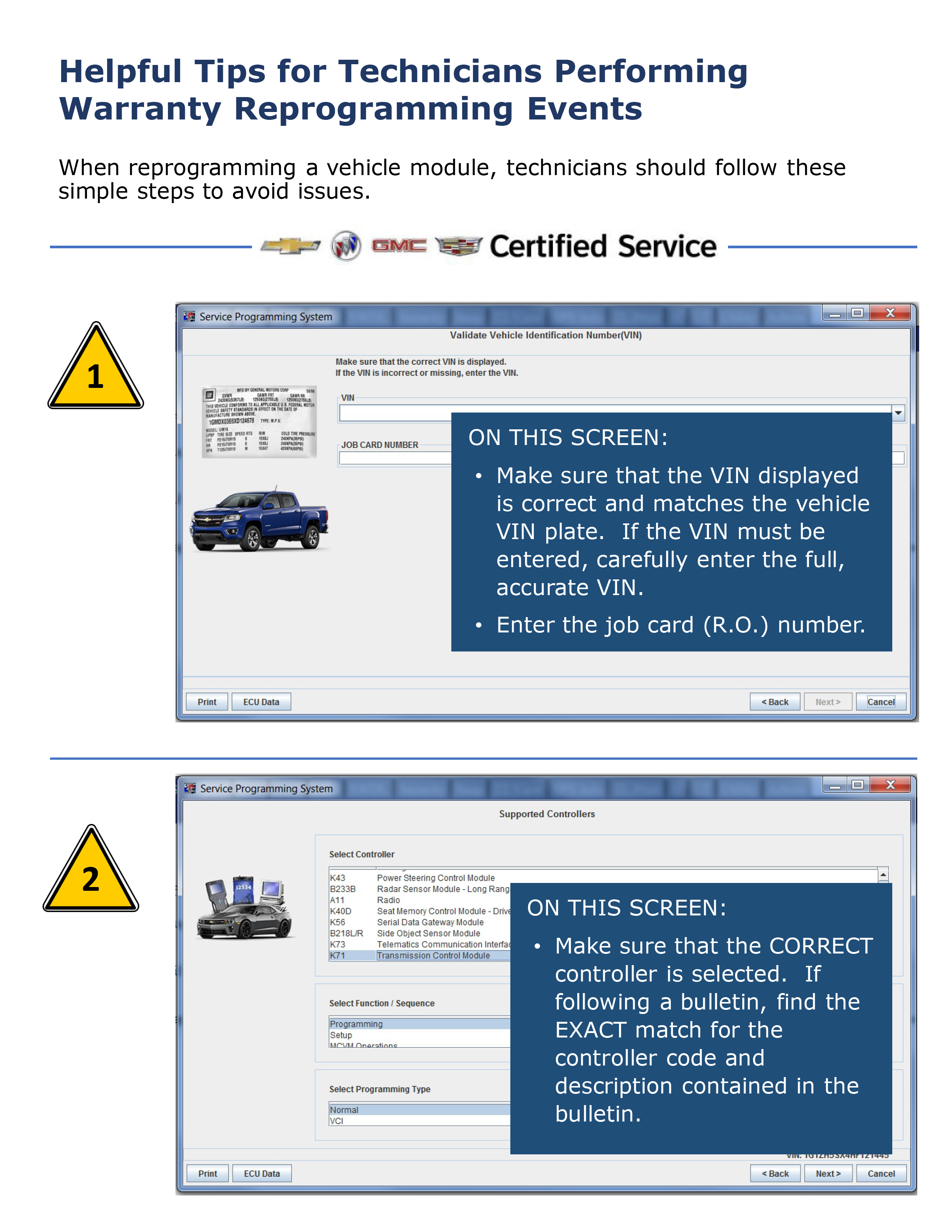

Ground repair connections are accomplished using one of the following replacement fasteners with a conductive finish:

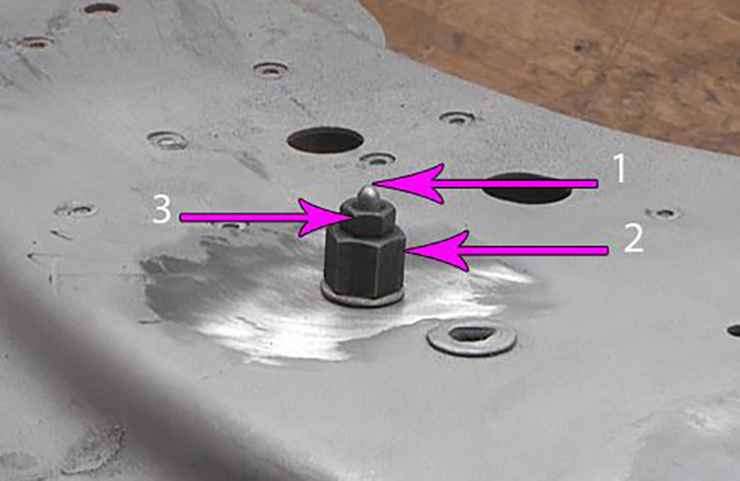

- Welded M6 stud and nut (Fig. 26)

- 焊接M6螺母和螺栓

- 焊接M8螺母和螺栓

Fig. 26

Fig. 26

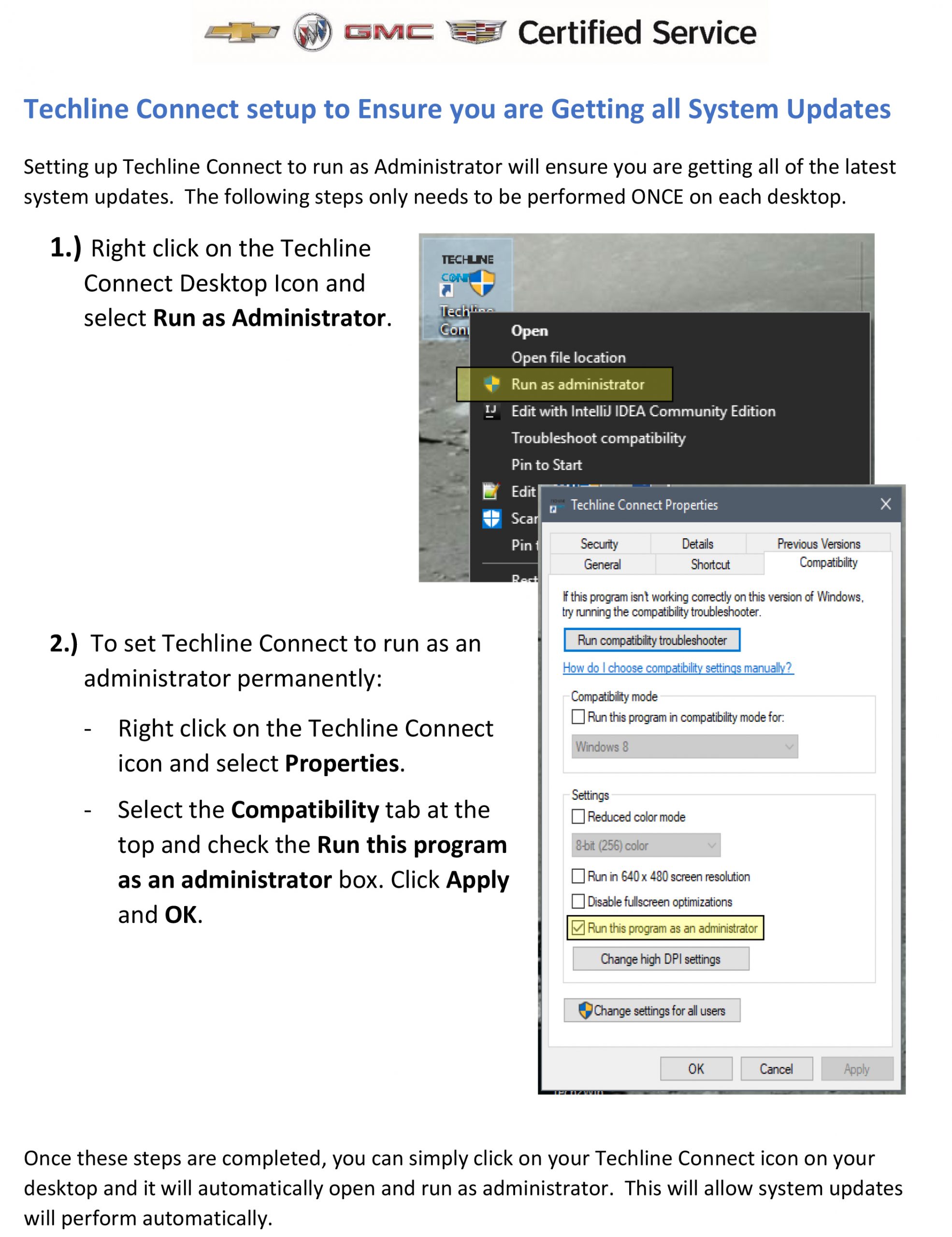

Before installing a new fastener in the current ground location or at a new mounting location, remove any grease from the repair area using a residue-free solvent. Select a location that has 20 mm (0.79 in.) clearance behind the panel surface and 20 mm (0.79 in.) clearance surrounding the stud flange.

After drilling the mounting hole (for a new location), remove any paint and primer from the area until bare metal is visible. (Fig. 27)

Fig. 27

Fig. 27

Install the appropriate new fastener and check that it is securely fastened without any detectable movement.

在安装M6导电铆钉螺柱时,用凹槽和面向铆钉螺柱的凹槽和喇叭侧组装铆钉螺柱(图27,#2)(图27,#1),然后是垫圈和M6螺母。(图27,#3)

Fig. 27

Fig. 27

Cover the stud threads with painter’s tape or equivalent and refinish the repair area using an anti-corrosion primer.

TIP:The surrounding area must be properly finished prior to the installation of the ground wire terminal and conductive nut to maintain a secure, stable and corrosion-free electrical ground.

Thoroughly clean the stud threads using a residue-free solvent. Once dry, apply dielectric lubricant to the threads.

TIP:Fretting corrosion is a build-up of insulating, oxidized wear debris than can form when there is a small motion between electrical contacts, causing electrical resistance across the connection.

Remove any corrosion or contamination on the electrical ground wire terminal. Install the terminal, tighten the conductive nut to the proper torque and verify system operation.

For additional details on electrical ground connection repairs, refer to the latest version of Bulletin #10-08-45-001. The bulletin includes a list of part numbers for the replacement fasteners and special tools.

- 感谢Sherman Dixon